Who is Ted Ings?

By Ella Houghton | Center for Performance Improvement®

The world around us is constantly changing and we need to be able to change with it.

If you want to be successful in any field, you need vision and adaptability, or the world will pass you by. The key to not only surviving but thriving in our modern world is to adapt and embrace change rather than fear it.

“The most successful people are those who accept and adapt to constant change.”

No one understands this better than Ted Ings.

Ted’s approach to business and life has always been a combination of vision and adaptability, and this has led to unimaginable success.

Anyone in the retail industry will tell you that a thirty-year career in sales is one thing, but a highly successful thirty-year career in sales is something entirely different, and that is what Ted Ings has managed to achieve.

Early on in his retail career, Ted had the vision to recognize that there are times when you need to adapt to the system but there are also times when you need to adapt the system.

As a young leasing manager at Fette Ford in Clifton, New Jersey, he made a huge impact on their sales, not because he was the most experienced salesman, but because he found a way to improve sales by adapting, and improving, an existing system.

By solely targeting Ford’s 24-month leasing program, dubbed "The Plan", in place of the conventional 48-month lease, Ted was able to increase their Red Carpet leases from 20 units per month to over 100.

He revolutionized the way Ford Division sold cars and put the name "Ted Ings" on the sales industry radar.

From there, his reputation grew, and before long he was leading retail process change initiatives throughout the automotive industry. Some of his biggest clients have included General Motors, Toyota, Lexus, Mazda, Mitsubishi, Subaru, Volvo, Nissan, Honda, Daimler, Renault, and Volkswagen.

Ted Ings is Retail

But not content with just changing the car retail industry, Ted quickly branched out and applied his marketing principles and vision in various other fields, including numerous Fortune 500 Companies including banks, indirect lenders, health and medicine.

Kaizen - The key to Ted's success

The key to building a successful sales business, in the motor industry or any other industry, lies in three letters – TQM or Total Quality Management. Total Quality Management, also known as "Kaizen" (meaning improvement in Japanese)or the "Deming" principle, is a comprehensive management approach and refers to activities that continually improve all facets of a business. It works horizontally across an entire organization and involves all employees, from the CEO to the assembly line worker, and all departments. It can even be extended to include suppliers and customers.

The key to successfully implementing TQM is to recognize that it is a daily process that all staff members have to buy into. It goes beyond simply improving productivity but rather strives to humanize the workplace and involve all staff in improving the company’s efficiency, productivity, and sales.

This is a concept that has been pioneered and implemented, extremely successfully, by the Japanese. In fact, it was in Japan that Ted learned about TQM and how to apply it successfully to all aspects of business. He also became a disciple of W. Edwards Deming, the man considered to be the father of TQM.

Ted Ings and the Total Quality Management (TQM) Process

William Edwards Deming (October 14, 1900 – December 20, 1993), an American engineer, statistician, professor, author, lecturer, and management consultant, pioneered TQM and used it to help turn around the Japanese manufacturing industry after the Second World War. Through the introduction of Kaizen, he made a significant contribution to Japan's reputation for innovation, high-quality products, and economic power.

“The worker is not the problem. The problem is at the top! Management!” ― W. Edwards Deming

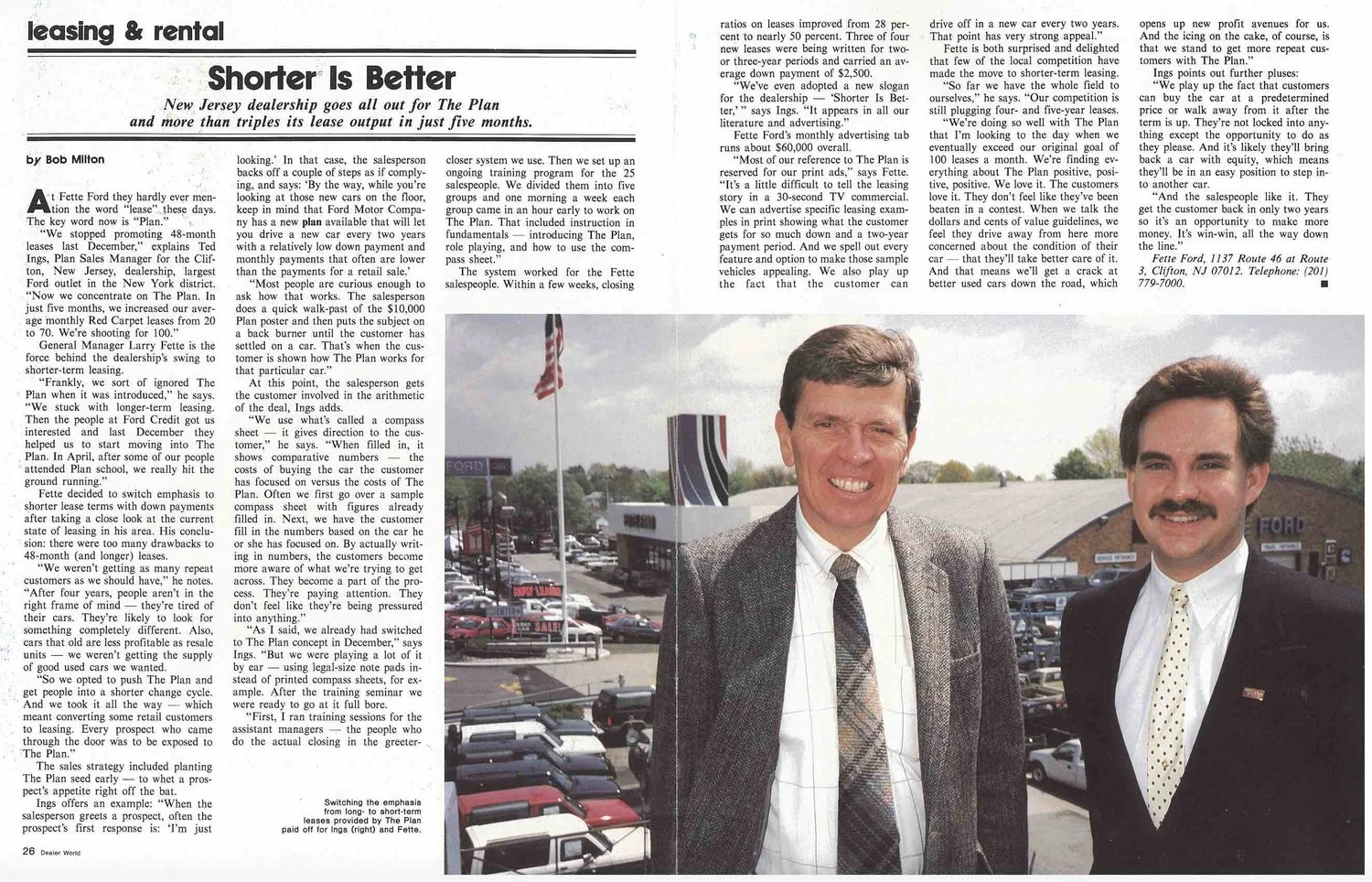

Ted Ings (right) is pictured in 1988 with Larry Fette, Dealer Principal at Fette Ford in Clifton, NJ. Under Ted’s guidance, Fette Ford became the # 1 volume 24-month Red Carpet Leasing Dealer for Ford Division of the Ford Motor Company.

By adopting Deming’s management theories, the Japanese were able to improve their manufacturing industry to such an extent that within ten years their products were flooding the America market and were no longer considered inferior to American made products.

Applying TQM Principles to the retail car industry

“Every system is perfectly designed to get the result that it does.” ― W. Edwards Deming

After spending significant time in Japan, Ted knew that TQM could transform the American car sales industry in the same way that it revolutionized the Japanese vehicle manufacturing industry. He studied Deming’s principles, and took what he learned in Japan, and successfully applied it to the vehicle retail industry.

Ted had the vision to adopt the TQM system used in the Japanese vehicle manufacturing industry and apply it to all areas of the car retail industry to improve everything from sales and marketing, to servicing and the overall customer experience.

Over the years, Ted has successfully worked with thousands of dealerships in North America (and around the world) as well as dozens of OEM’s, and they have all benefited immensely from his experience, expertise and the implementation of a TQM system that works for them.

Ted Ings has seen firsthand how TQM creates a whole new customer experience and level of satisfaction. One of his main areas of focus in dealerships is the customer service counter, or rather lack thereof.

Ted has been on a 25-year crusade to move the customer and service advisor from the counter to the vehicle. The reasoning behind this is simple, the customer is there to discuss their vehicle and the best place for them to do this is at the vehicle.

Ted’s years of experience in retail have given him the ability to walk into a dealership and, within a matter of minutes, know exactly who's who and where they're failing.

He can then tailor his approach, and the TQM principles, to deliver maximum effectiveness. Not because he is a mind reader, but because he comes from a retail background and spent ten years selling cars and managing dealerships.

Ted knows how to work with large groups and offers interactive facilitation sessions for dealerships. He also works with Original Equipment Manufacturers (OEM’s), primarily focusing on Field Teams and the best approach to use with retail dealers.

Ted founded the Fixed Ops Roundtable conferences in 2019 and has created an exciting, new movement in the automotive world.

Ted has been in the retail car business since 1981 and during his career in retail training and development, he has worked with dozens of America's richest companies.

Ted is a 5-time NADA (National Automobile Dealers Association) Convention speaker and is one of their highest-rated presenters.

He has successfully implemented dozens of initiatives for OEM’s and Total Quality Management processes at thousands of dealerships in North America and around the world, revolutionizing the way vehicles are sold.

This makes him an invaluable asset to his clients and they get both the benefit of his vision and his experience.

One would assume that by now Ted has seen everything there is to see and done everything there is to do. But one of his greatest assets is his attitude, and Ted has stayed at the top of his game by remaining a student of his craft, constantly learning and adapting to improve both himself and the way he does business.

Ted Ings is Executive Director for the Center for Performance Improvement® and our lead facilitator. Ted is always looking outside of the retail auto industry for inspiration and best practices that can be adapted to increase car sales and customer service.